The process we use to create a Moix is completely individualized, each of our works requires a complex and detailed study.

Based on a photograph we developed the prototype of a Moix.

We analyzed in detail the physiognomy and factions, thus locating the features that bring us aesthetically. During this phase we also adapt the image to the size of Moix obtaining the number of drops and parts needed for its development.

Once transformed the image adapt palette that conform to our palette of green glazes. If necessary changing tones until the most appropriate results, this will be the prototype Moix.

Once realized the prototype ceramics started working for it, we only use porcelain stoneware made with 100% natural raw material.

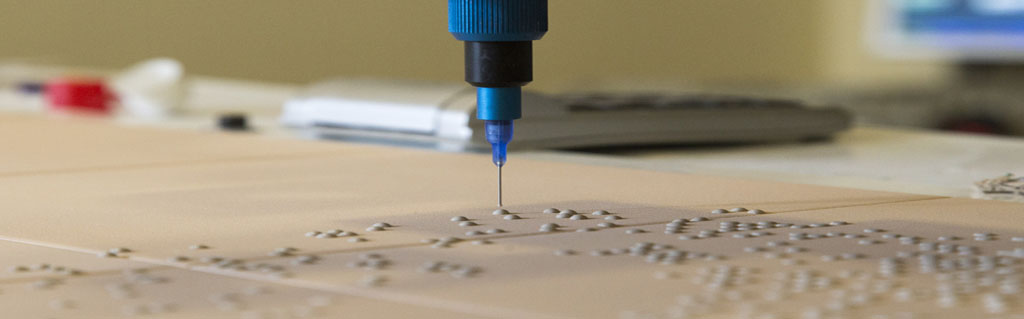

For the phase of Arab craftsmanship merge glazed with innovative processes developed exclusively Moix. The enamel drop by drop is done making images of more than 40,000 points per m2.

We have a wide range of glazes. All ecological.

To complete the manufacturing process proceeds to the baking of the pieces in furnaces reaching 1300 degrees.

The end result are pieces of glazed bricks of high hardness, resistance to extreme temperatures and waterproof. Therefore Moix is suitable for both indoor and outdoor, also they resist moisture very well so would not be affected in coastal areas.

A Moix can be obtained in individual pieces for subsequent assembly or pre-assembled on plates for indoor or outdoor. We also offer the possibility of adapting special frames for the same.